U.S. Army Corps of Engineers Visits NREC for MatSinking Project Update and Armor 1 Build

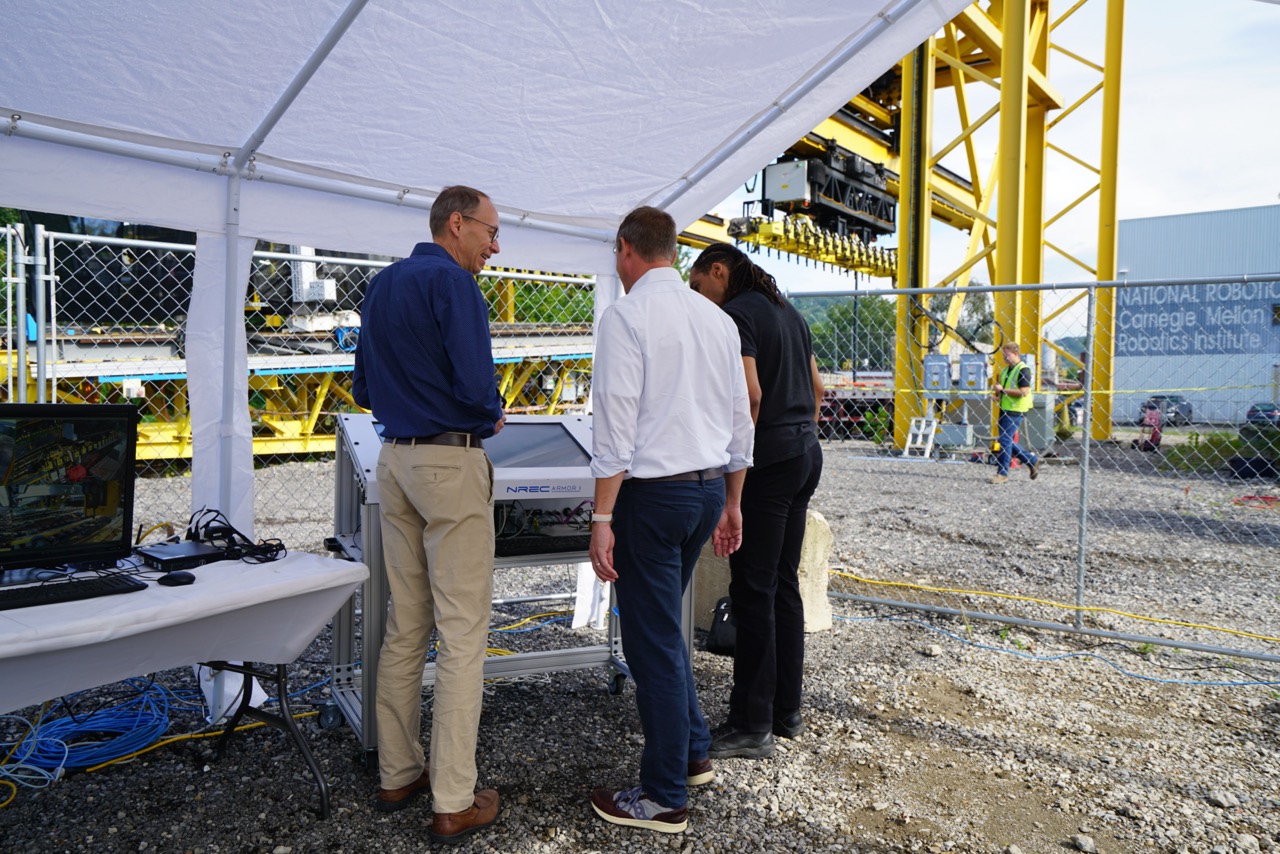

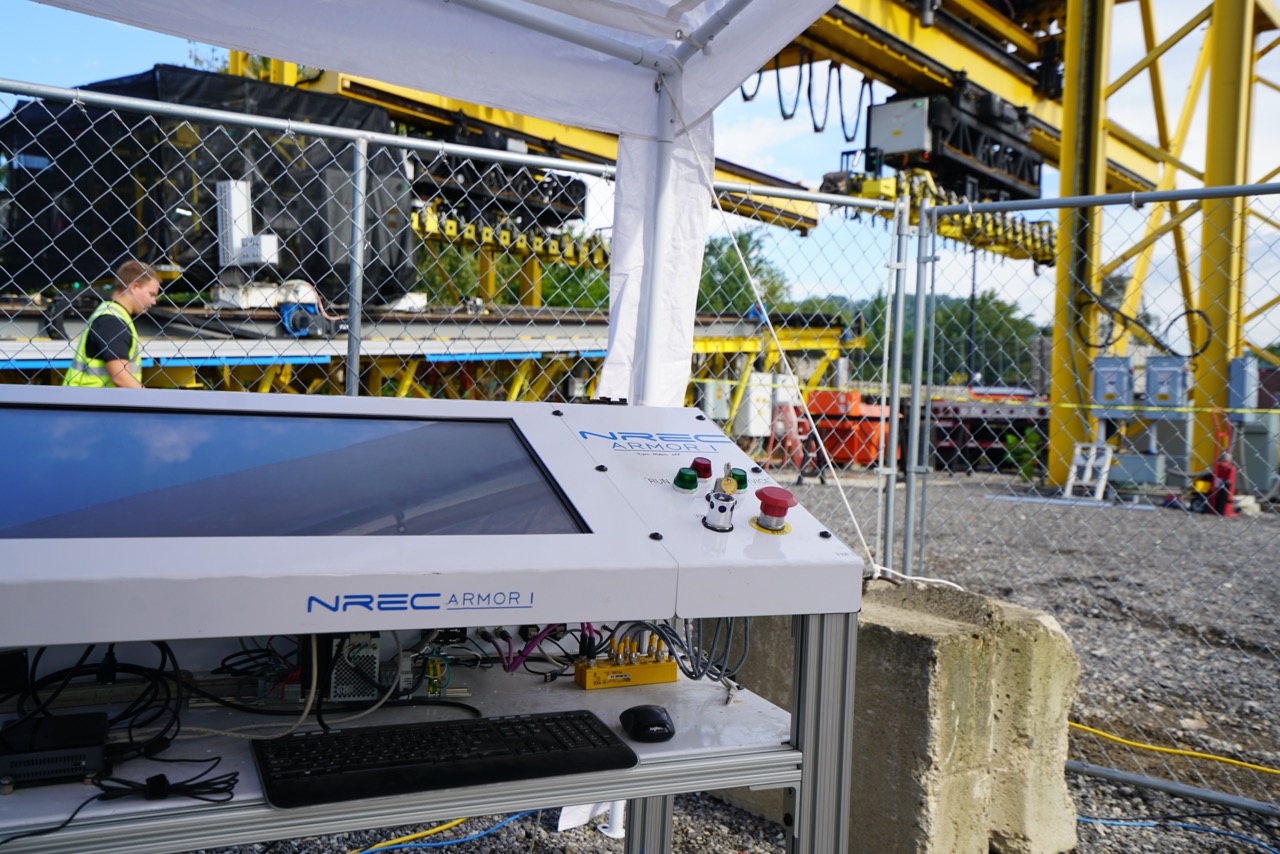

Recently, sponsors from the U.S. Army Corps of Engineers (USACE) Vicksburg District, USACE Marine Design Center, ship builders from Thomas-Sea Marine Constructors, and representatives from team members SIA Solutions, Bristol Harbor Group, and ABS Group traveled to the National Robotics Engineering Center in Pittsburgh for a site visit highlighting the Armor 1 Mat Sinking Unit. Armor 1 in its current production-intent prototype form involves two robotic cranes suspended from an overhead gantry system. The full system is designed to revolutionize the USACE’s revetment operations along the Mississippi River and will be equipped with six 24-ton cranes.

Each robotic crane, or arm, picks up rows of concrete squares which are then placed on the barge platform, precisely aligned using machine vision techniques, and efficiently fastened together using thirty-six (36) automatic tying mechanisms. Once secured, the rows of concrete form a complete “mattress” intended to line, or “armor,” the river banks, stabilizing its course while preventing erosion.

The group of stakeholders met to review monthly briefings on project updates, timelines, challenges, and solutions. NREC engineers shared key improvements on specific software components which incorporate auto recovery steps, auto retry, and auto re-tensioning of cables after each launch. These automatic updates reduce down time between steps in the build process and require less user intervention, ultimately freeing up operators for more skilled and comprehensive tasks.

Following presentations and discussions, the group observed a live mat-sinking build from load to launch outdoors in NREC’s front yard. After the successful demonstration, guests took the opportunity to climb aboard the recently assembled mattresses and inspect components of the entire system up close, asking questions and conversing with project engineers and technicians.

"Today’s visit was very beneficial for the larger Armor 1 team to be on site [at NREC] and experience the entire robotic process," — Jim Arthur, Project Manager, NREC

“Our partnership with USACE and NREC reached a significant milestone during this visit. The land-based robotic prototype performed exceptionally well. SIA Solutions looks forward to transitioning from testing to full-scale manufacture and assembly of the final prototype system,” said Jon Vernau, Senior Vice President at SIA Solutions, a Salas O’Brien Company.

Many individuals tested the improved manual tying tool, which NREC designed and built during a previous project phase. The new manual tying tool is powered electrically by a rechargeable battery instead of the previous pneumatic design, thereby reducing the overall weight and mobile restrictions of the hand-held machine. These improvements significantly increase the maneuverability of USACE personnel who are responsible for carrying the tying tool along the mattresses to manually complete remaining ties while the Mat Sinking Unit is in operation on the water.

"Today’s visit was very beneficial for the larger Armor 1 team to be on site [at NREC] and experience the entire robotic process. We still have work to do between our current state and reaching full system operations, but today we were able to effectively demonstrate progress in the right direction," said NREC Project Manager Jim Arthur. "I greatly appreciate the support from everyone at NREC and all our partners who contributed to ensure this demonstration was successful."

Once deployed on the Mississippi River, Armor 1 will replace the Corps’ current Mat Sinking Unit, originally built in 1948. The development team for Armor 1 consists of NREC, SIA Solutions, Bristol Harbor Group, and ABS Group. The program is funded by the U.S. Army Corps of Engineers.