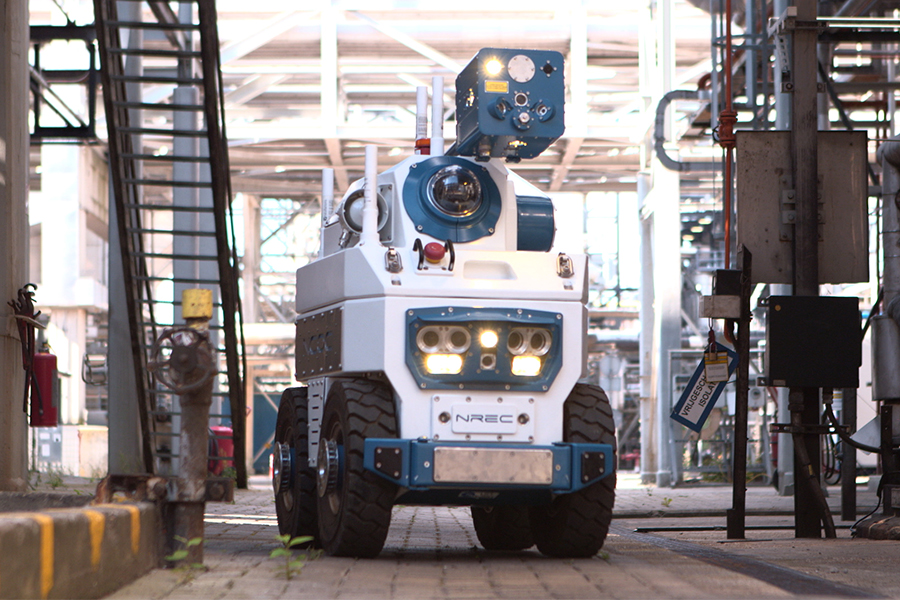

Shell deploys Sensabot, a mobile inspection and monitoring robot developed together with NREC

NREC recently worked with Shell to help transform productivity, efficiency, and safety within operational plants through the development and implementation of a mobile inspection robot.

The rugged and versatile Sensabot passed the IECEx-Zone 1 certification and is now operational. It will perform a wide variety of inspection and monitoring tasks in both manned and unmanned Shell ventures. The culmination of multiple years of development work, Sensabot provides cost-effective and safety-enhancing technology in exceptional environments and operational structures. Shell is planning to deploy the semiautonomous rover on an unmanned island within the $50 billion Kashagan development in the Caspian Sea—an oilfield known for high levels of a poisonous gas called hydrogen sulfide.

Sensabot features a mobile robotic base paired with a sensor boom housing a suite of inspection sensors. It is able to operate in extreme temperatures as well as within explosive and toxic atmospheres. “Sensabot is the first explosion-safe resident and mobile robot,” noted Alisa Choong, EVP of Technical and Competitive IT at Shell. A human operator remotely drives Sensabot and uses its sensors to inspect pipes, fittings, and valves. The data it collects via operator assist may be shared with employees and stakeholders via a number of connectivity options including smartphones, tablets, and site-specific monitoring equipment.

The robot was designed to perform on-site inspections in potentially hazardous environments, isolated facilities, and other locations that are difficult or dangerous for personnel to access. Sensabot exceeds the IECEx Zone 1 standards for explosive environments and ANSI safety standards for guided industrial vehicles. IECEx Zone 1 environments are spaces in which an explosive atmosphere occasionally occurs during normal operation. The explosive atmosphere could consist of a mixture of air along with dangerous substances in the form of gas, vapor, or mist. Adam Serblowski, Frontier Automation Engineer at Shell states, “No one has ever built a robot of this size and this complexity to this standard before.”

Sensabot is designed for extended maintenance intervals of six months, thereby reducing the need to send technicians to the robot's location. The operations and data collection time is significantly streamlined by the robot’s self-docking and recharging capabilities. Sensabot is setting the standard for guided vehicles within the energy market, using safe and effective data collection technology.